According the forks adjusting structures, Riggerte fork positioners have 4 series, first K series,second G series, third E series and the last one H series.

- H series is normally for a customized width or heavy duty forkift from 4 to 16 tons. We design this according clients' requirements. The model No. sample is FP-5TH-S1550. FP means fork positioner, 5 means loading capacity 5 tons ,S means side shifting function, 1550 means overall width.

- Frame:customized as per clients requirements

- Independent Side shifting cylinder

- Riggerte designed adjusting structure

- Lead time is short

- Easy to assemble and maintain.

2. K series fork positioners usually for 2~3.5Tons forklift, width range from 900~1350mm. It's forks adjusting structure is same as Cascade fork positioners.

The model No. sample is FP-2.5TK-S1040. FP means fork positioner, 2.5 means loading capacity 2.5 tons ,S means side shifting function, 1040 means overall width.

- Frame:Standard 2~3.5T side shifter

- Independent Side shifting cylinder

- Cascade forks adjusting structure

- Lead time a little bit longer Adjusting structure not stable and strong

- Total Weight around 70~100KGS,require one set of special tools to assemble and maintain.

3. G series fork positioners is similar with Kaup fork positioners, and it's model number rules is same as above. But this fork positioners is more easier to assemble and maitain. The whole structure is more stable than K series, but heavier than K series.

- Frame:Standard 2~3.5T side shifter

- Independent Side shifting cylinder

- Cascade forks adjusting structure

- Lead time a little bit longer Adjusting structure not stable and strong

- Total Weight around 85~115KGS, easy to assemble and maintain.

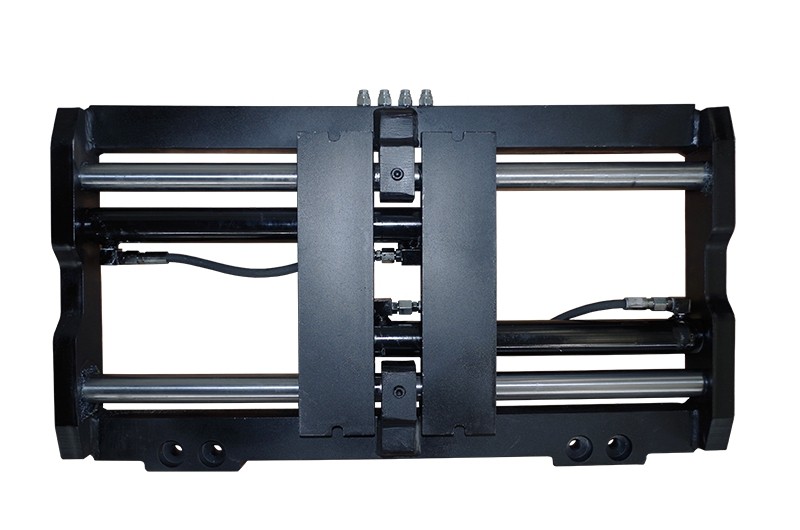

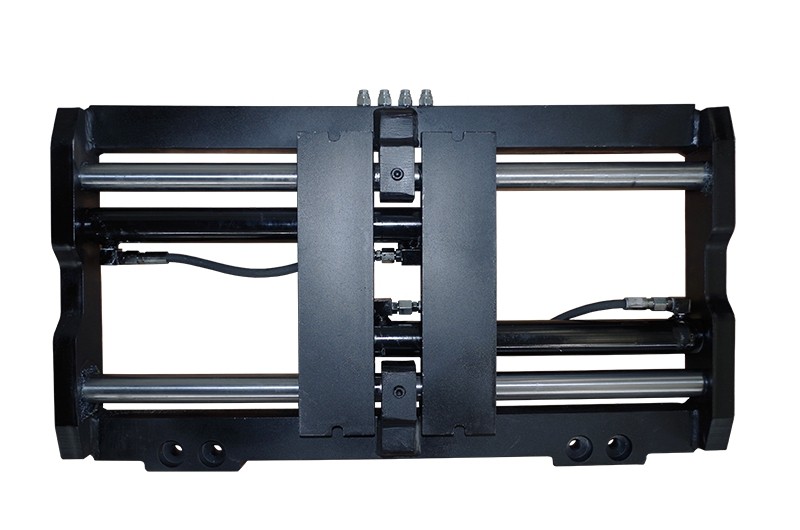

4. E series Fork positioners has two guiding pins to support forks sliding smoothly and stable. It's structure is strong and stable than K and G series, but price is a little bit higher.

- Frame:Cutting and welding steel plate

- Side shifting by cylinders stroke and contract

- Riggerte double-pins type adjusting structure Lead time is the best. Adjusting structure is most stable and strongest

- Total Weight around 130~150KGS

- Easy to assemble

- Price a little expensive than other two series